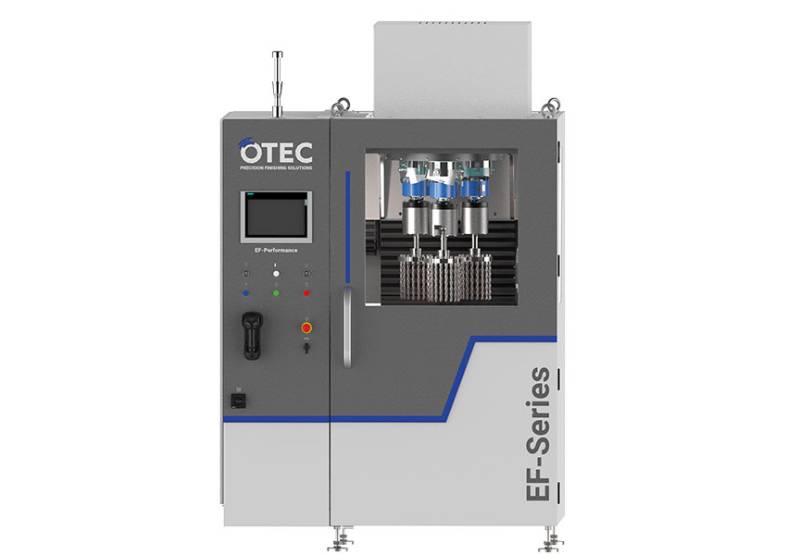

EF-PERFORMANCE

The innovative combination of Electro Finishing Technology with established mass finishing technology from delivers high-gloss perfection for workpieces with complex geometries in diverse sectors. This enables maximum gloss even in the smallest of corners and surface polishing without micro-scratches for large parts as well. Reliable, precise and efficient, this technology sets new standards for surface quality and cost-effectiveness.

APPLICATION AREAS

Sectors: jewellery, dental, medicine, industry, tools

Materials: gold, silver, copper, brass, cobalt chromium, tool steel, stainless steel, Inconel, aluminium

HIGHLIGHTS OF THE EF-PERFORMANCE

-

High-gloss polishing with maximum gloss and no micro-scratches

-

Precise processing in hard-to-reach areas such as inner contours

-

Intricate geometries are maintained and are smoothed and polished gently

-

Short, reproducible process times less than 30 min.

-

Minimal media jamming thanks to tiny, spherical particles

-

Cyanide-free particles in special developed conductive liquids, which are safe for users

PROPERTIES

-

Capacity of 3 stations, each with a working space measuring 180 x 180 mm (diameter x height) for 27 workpieces with a component size up to 60 x 40 mm (diameter x height)

-

Manual loading with a simple clamping system

-

Easy, ergonomic machine handling

-

One-handed loading by simply suspending the holders

-

Abrasive temperature and conductivity monitoring ensures process stability

-

Intuitive touch panel control and recipe database with workpiece-specific standard programs

-

Industry 4.0 with remote control, remote maintenance and OPC UA interface

|

|

| Loading with 27 knee joints at 3 stations | Loading with 60 drills at 3 stations |