UNISEPA

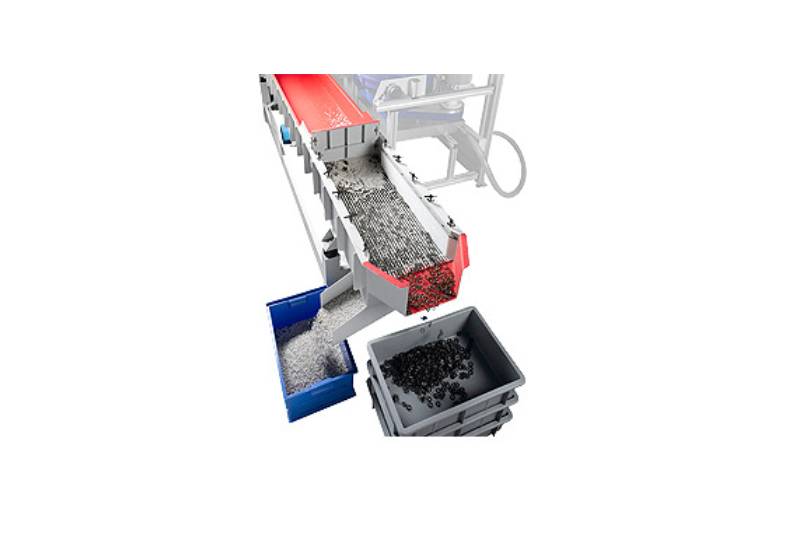

The new UNISEPA screening unit from OTEC is a universal system designed for separating vibratory grinding abrasives and workpieces. A range of settings such as flow regulation, vibration frequency and vibration amplitude make the UNISEPA suitable for virtually any screen separation task.

UNISEPA SEPARATOR UNIT

Mobile screen separation: compact, mobile, flexible

The mixture to be screened out is poured into the hopper system of the screening unit by hand and conveyed onto the screen by vibration. A flow regulator at the hopper enables the ideal rate of flow to be set. The speed setting enables the vibration frequency to be adjusted to suit various mixtures as required (screening speed). The amplitude of the screening unit can also be increased or reduced by varying the oscillator weights on the vibration motor. A greater amplitude, for example, allows scoopable workpieces to be removed, whilst a lesser amplitude enables sensitive workpieces to be separated gently. More information here.

-

Fast and user-friendly screen change

-

Controllable rate of separation

-

Extremely cost-effective

-

Mobile for greater flexibility