PEENMATIC 950ZIDA-SAT

Introducing the SECKLER sandero, a natural extension of SECKLER’s robomation product range. The SECKLER sandero is an automated micro sandblasting machine that satisfies even the strictest of quality demands, and increases the eco-nomic efficiency of the sandblast-ing process.

The SECKLER sandero is designed to accommodate parts up to a maxi-mum diameter of 80 mm and a maximum length of 150 mm.

It is comprised of a stand-alone blasting system with rotary table and eight workpiece stations. It is possible to have a maximum of four individually programmable blasting nozzles at each table position. After the blasting process, the workpieces are carefully blown off so that they can be removed dust-free from the parts fixture.

High flexibility

User-friendly programming for the blasting of small parts in the widest possible variety of shapes and forms

Better process controlling

Optimal mixture of blasting material to reduce consumption of blasting media

High and repetitive quality

The desired surface quality with flexible parameters

| For the SECKLER sandero we have developed a new clamping system with rubber protection |

Robot above pallet consists of:

+ Double gripper head + Pallet stacking box + Flip-over station |

The robot is loading and unloading the rotary table of the micro sand-blasting system. |

|

|

|

Basic configuration

+ Rotary indexing table with

8 satellites

+ 4 blasting gun units

+ Blasting pre-acceleration

of blasting media

+ Selective fine grain separation unit

+ Surface micro filter

Scope of application

+ Automotive

+ Watch/Jewelry

+ Medical technology

+ Consumer goods

Options

+ Vertical linear unit for blasting nozzles with a stroke of 150 mm

+ Automated blasting shot injection

+ Suction with dust container

+ Noise protection cell for suction and injection

Flexible software with a user-friendly interface

The SECKLER sandero software allows the controlling of the following micro sandblast and robot parameters:

+ Material pressure and dosing of the micro sandblast quantity

+ Feed pressure

+ Blasting time

+ Number of pallets

+ Number of parts

+ Flip parts yes/no, before or/and after micro sandblasting

+ Workpiece administration for up to 176 parts or unlimited by CSV-file

What is the iepco micro sandblasting technology?

It is a dry micro blasting method with a defined blast media (grain size, grain hardness and grain geometry) to positively influence the micro topo-graphy of the surface in various forms and qualities.

Goals of the iepco micro sandblasting technology

+ Surface cleaning

+ Surface compression

+ Increase of the bearing share

+ Micro deburring

+ Adhesive base preparation

+ Surface texturing

+ Exact defined edge fillet

+ Removal of “droplets” and sharpening burrs

+ Compression, smoothing and polish of workpiece surface

+ 100% reproducible

Blasting media

+ Aluminum oxide

+ Ceramic blasting media

+ Silicates

+ Stainless blasting media

+ Tempered glass balls

+ Synthetic blasting media

+ Organic blasting media for sensitive mold cavity

+ Blasting media with tribological additives on surface of blasting shots

iepco is the expert for a perfect finishing of surfaces. The leading know-how is based on 40 years of experience in this field. Combined with the most modern technology and comprehensive advisory service iepco offers together with SECKLER cost efficient overall solutions – specially tailored to your individual requirements.

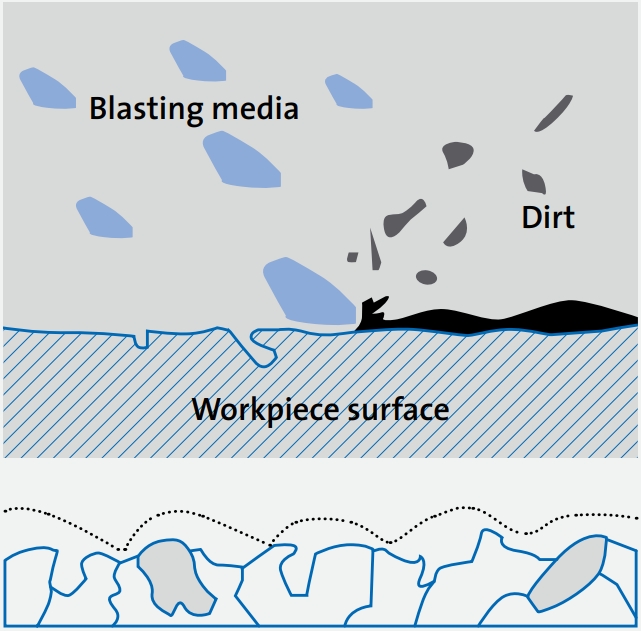

1st level: Cleaning

Clean and uniformed surfaces with fine, sparkling micro blasting media. At the same time, all the loose parts are removed. It can also be provided with an adhesive base preparation.

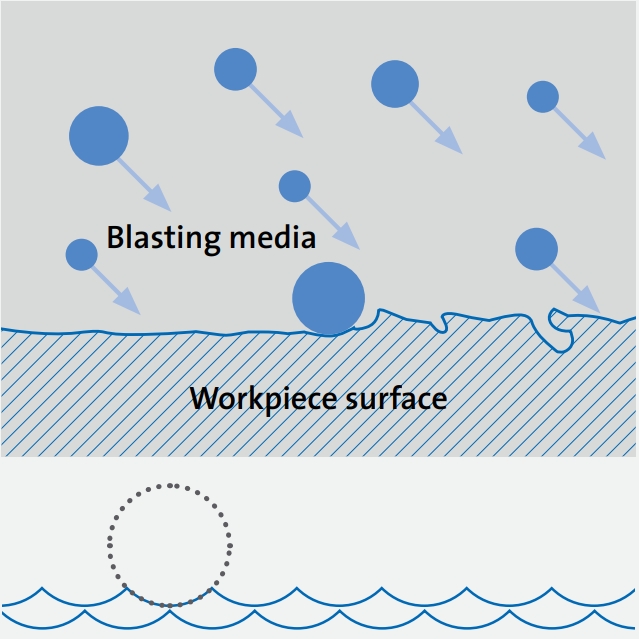

2nd level: Compression

Compression of the surface with simultaneous embedded additives inside the surface. Increase of the tribological characteristics for various applications.